Views: 8900 Author: Site Editor Publish Time: 2013-04-09 Origin: Site

vs

vs

1.True non blocking function

The open spiral large channel of the pump has the characteristics of high efficiency and no blockage. It is easier to transport large solid and long fiber materials, and the ability to pass through particle diameter is far superior to other impeller types of water pumps

Non clogging and non overload spiral centrifugal impeller, capable of rotating soft solids on its own to prevent long fibers and solids from being entangled by the blade edge when entering the suction port, causing blockage.

The blocked pump added three additional costs:

■Cost 1. Pump blockage leading to reduced efficiency

■Cost 2. When the pump is partially blocked, it will reduce the output volume

■Cost 3. Cost of clearing pump blockages

2. Soft conveying characteristics

Minimally destructive to the medium, it can maintain its original physical state. This feature can maximize the protection of the size of flocculent particles in the returned sludge during pumping, ensuring the effectiveness of sludge treatment.

Changes before and after transportation of activated sludge by ordinary sewage pumps

Changes before and after conveying activated sludge by HRS / HRSB pumps

3. Excellent hydraulic performance

■ High efficiency = Low operating cost

The high-efficiency zone is particularly wide, and the water pump efficiency is high throughout the entire operating range, with obvious energy-saving effects.

■ Steep performance curve = Smooth operating point

When the water level of the collection tank changes greatly, the flow rate of the water pump does not change much, which can ensure continuous and stable operation.

■ Lower Net Positive Suction Head required (NPSHR, green curve in the right figure) = High self suction capacity

When operating at a lower water level, the impact of cavitation can be reduced. Under the same conditions, the installation height of the water pump can be increased,

The lower water level that can be pumped can also be reduced, reducing the number of motor starts

■ Flat power curve (red curve in the right figure) = No overload area

The power of the entire operating range is flat, effectively preventing motor overload caused by water level fluctuations.

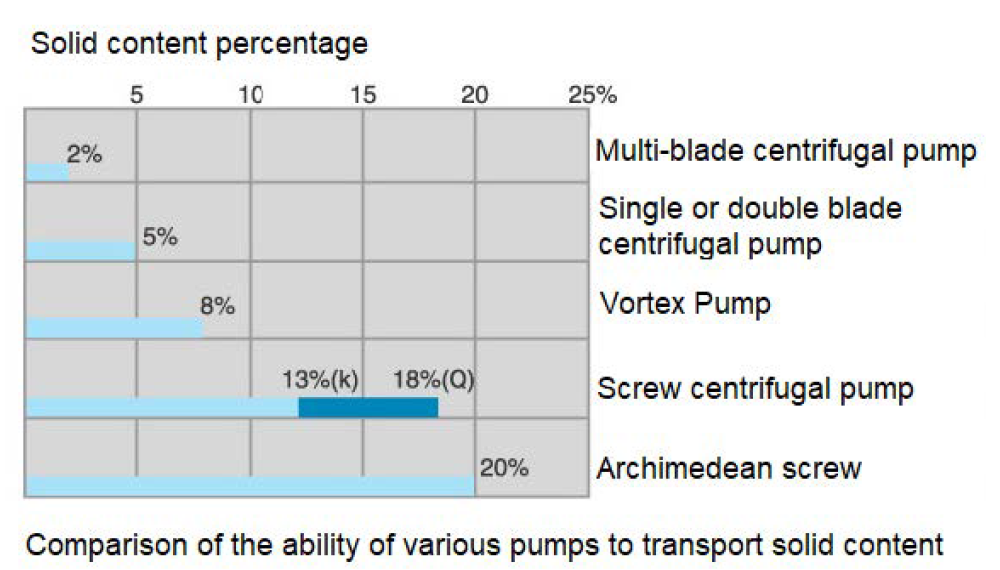

4. High solid content conveying

■ The composition of sewage medium is complex, with many impurities. The high content of solid conveying capacity can effectively reduce the occurrence of blockage during the conveying process and better cope with different working conditions.

■ Especially suitable for untreated raw sewage or rainwater collection systems.

5. Sustainably maintaining the efficiency of new pumps and facilitating maintenance

■ The impeller clearance can be adjusted through gaskets (non adjustable lining)/three external adjustment bolts (adjustable lining), so that the pump can always maintain the efficiency of the new pump during operation and save operating costs.

■ After long-term operation and wear, pumps usually only need to replace one inner lining, which is convenient for maintenance and low in cost.

Pump Q-H characteristics, Efficiency, Motor power

■ The steep Q-H curves shows little change in flow rate when the pump head changes. (Refer to the dotted line in the left figure for identification) , can ensure continuous and stable operation of the pump.

■ No overload power curve to achieve matching smaller motor power, more energy-efficient.

1.Pump Q-H characteristics, Efficiency, Motor power

■ Smaller motor power means smaller starter and number of starts, smaller cables, and smaller energy support, and reduces energy consumption.

■ With the same solid conveying capacity, screw centrifugal pumps have higher efficiency and wider efficiency zones.

2. Efficiency repairable characteristics

All sewage pumps that can provide high efficiency need to have some form of clearance to maintain their high efficiency.

■ HRS / HRSB screw centrifugal impeller has a gap between the blade edge and the suction / lining, which can be axially adjusted to achieve the repair of pump efficiency and basically achieve the efficiency of a new pump.

■ Ordinary sewage pump (CNP WQ): The clearance of the inefficient water pump cannot be adjusted, resulting in a continuous decrease in efficiency and flow rate. Finally, it can only be sent back to the factory and replaced with a hydraulic part to solve the problem.

3. Comparison of efficiency in transporting sewage and sludge

■ Ordinary sewage pumps (CNP WQ) : The curves of sewage pumps will significantly decrease when transporting sewage and sludge. (refer to the curve on the left)

■ HRS pumps have the smallest amount of change in this regard.